|

|

|

News

|

Living With

Your Plane: The joy of living with your plane

Bill

Tuccio

8/6/2003

In January of this year I received

the approval I needed to start building my own hangar: My wife

Barbara said yes! In January of this year I received

the approval I needed to start building my own hangar: My wife

Barbara said yes!

As I write this, I have just moved my

1994 Maule MX-7-180A into my new hangar. And while the

construction process had its challenges, they all paled in

comparison to the initial approval from Barbara.

Once

that was granted, we were fortunate enough to find a wooded

lot on a private airport community in Holt, Fla., called

Yellow River. After obtaining a copy of the covenants and

restrictions for the community and talking to other owners, it

was clear this community allowed hangars without homes. All

communities are different. It is important to find out what

your prospective aviation community allows in their documents

and what happens in practice.

By the time we closed, I

had already met with a local contractor who would clear the

land. My wife and I had marked as many trees as possible to

keep on the property while allowing for the placement of the

hangar. In a couple of hours on a Saturday morning, his

bulldozer cleared our 2/3 of an acre of trees.

Another

thing I did before the closing was to start comparing quotes

on buildings. I compared a variety of designs from

traditional, large span steel buildings to arch style

buildings to geodesic domes. The environment of the panhandle

of Florida played a large part in the questions I asked. This

environment requires a building that can meet Florida

hurricane building codes, avoid termite problems, and provide

some heat relief. After acquiring quotes from approximately

six different manufacturers and then adjusting those quotes to

compare apples to apples, I was able to select Ludwig

Buildings in Louisiana.

Equally important in the

purchase was the door selection. I was initially surprised to

find the door cost nearly half as much as the building.

Consider if you need a door at all. I spoke to some

well-reputed people who said the primary need for a door is

security, not the weather. Unfortunately, I had not considered

this advice until after my order had already been placed with

Hydroswing.

I did follow my purchase decision through

by making sure the door manufacturer and the building

manufacturer worked out all compatibility details. While both

manufacturers were very professional and did not need my

input, it gave me peace of mind to get verifications from both

parties that things were going to work out.

As Ludwig

and Hydroswing did their offsite construction, they sent

documents along the way that would be necessary to continue

construction. The first key document was the anchor bolt plan,

which allowed a local engineer to design the foundation. The

next key set of documents were the Florida engineer-stamped

plans for the door and building. With the foundation, building

and door plans in hand, I went off to the building inspector

for my approval.

I came across a little resistance

since politicians generally don't write a paragraph into the

law books for "residential hangars." The building inspectors

had to find an appropriate category and in my case it

qualified essentially as a shed. While demeaning to my

lifelong dream of having my own hangar, I didn't argue. The

permit allowed us to get electric run to the property and

break ground for the foundation.

I had looked around a

bit for someone to do the foundation and obtained some

references. I met a local contractor, David, who did land

clearing, foundation work, and marine construction. I hired

him to take on the whole project, including the foundation and

hangar erection.

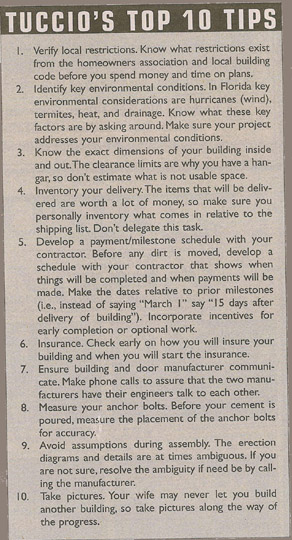

David formed out the foundation and

installed the anchor bolts according to the plan. I had been

advised by numerous people to double-check the measurements of

the anchor bolts. I checked eight of the 10 anchor bolts on

the job. Unfortunately, it was the two I did not measure that

were off by about six inches. David was able to correct the

anchor bolts during the pour when he caught the error, but had

I executed my responsibility properly, things would have gone

smoother.

I was fortunate that the delivery of the

building and door occurred on the same day. This made for an

efficient use of the heavy equipment needed to get the steel

off the trucks. Both manufacturers delivered every item in

perfect condition.

I spent the weekend inventorying

every one of the more than 200 items on the shipping list for

the building, which was time well spent. Had any items been

missing, resolving the discrepancies before erection would

save valuable time.

The heavy steel of the building was

put up using a bucket loader and chains. As one can imagine,

the large steel trusses of the building are the heaviest part

of the construction and a bucket loader, fork lift or crane is

a must. The supporting steel girts (wall beams) and purlins

(roof beams) were light enough that they could be lifted into

place. Once all the steel was put in place with the hundreds

of nuts and bolts, the 2,000-pound door was lifted and welded

into place.

The steel construction took about a month,

due to a combination of weather and David's workload. With

ideal conditions and a couple extra hands, the steel can be

put up in a couple days. When the weather was not cooperating,

David was able to finish grading the property and moved about

500 yards of dirt to form a gradual slope and pad in front of

the building.

With the steel frame completed, it was

time to begin the sheeting. Early on I had been advised to

insulate the building. Being from Connecticut, I didn't really

understand why a building in Florida needed insulation, but I

came to understand that the combination of heat and noise was

greatly reduced by insulation. The insulation required that it

be in place before each piece of sheeting was applied, which

adds some time to the sheeting process. Each piece of sheeting

for the roof was about 25 feet in length, and about 12 feet

for the walls. Handling these large sheets requires some low

wind conditions and care to avoid injury.

About three

months after clearing the lot, the final trim pieces and

gutters were in place and I passed the final inspection. That

night I proudly moved my plane out of the elements and into

the hangar.

After breathing a sigh of relief, I looked

around and realized I had so many more things to do. I still

need to thoroughly clean the yard, plant grass, and adjust the

approach to the hangar. I'm going to try to slow down and

enjoy these steps. After all, that is part of what "living

with your plane" is all about.

mailto:comments@generalaviationnews.com

| |

| |

.gif)

.gif)

.gif)

.gif)

.gif)

|